Shanghai Microelectronics lithography machine patent exposure can improve lithography machine accuracy – Hardware-cnBeta.COM

Recently, Shanghai Microelectronics held a new product launch conference and announced the launch of a new generation of advanced high-precision large-field lithography machine. At present, Shanghai Microelectronics has reached sales agreements with a number of customers for a new generation of advanced packaging lithography machines, and the first one will be delivered within this year.Photolithography is a technique that uses light to display and copy mask patterns. The integrated circuit is formed by a projection device of image patterns with different mask patterns on the substrate to manufacture integrated circuits, thin magnetic heads, liquid crystal displays, a series of structures such as panels or micro-electromechanical systems.

being able to:

2021 Tmall Double 11 Red Package Collection Page

Double Eleven Receipt Entrance “Beijing Poster Number One” JD 2021

In the past few decades, the technological level of exposure equipment has been continuously developed to meet the needs of smaller line size, larger exposure area, higher reliability and productivity, and lower cost. However, current lithographic projection objective lenses still face problems such as small numerical aperture, low resolution, narrow applicable wavelength range, fixed numerical aperture, and high manufacturing cost of aspherical lenses.

For this reason, Shanghai Microelectronics has applied for a patent titled “Lithographic Drop Target and Lithographic Machine” on December 30, 2018 (order number: 201811648523.1), and the applicant is Shanghai Microelectronics Equipment (Group) Limited by shares.

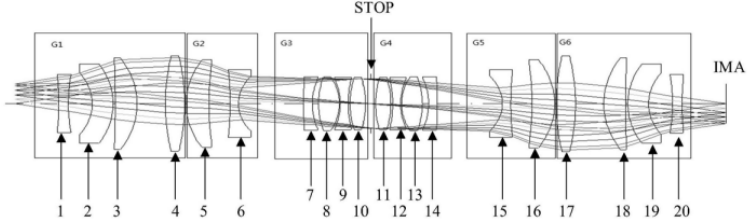

▲ Figure 1 Schematic diagram of the structure of the lithographic projection objective lens

Figure 1 represents a schematic diagram of the lithographic projection objective structure proposed by the present invention, including the first lens group, second lens group, and third lens group, as well as the fourth lens group and fifth lens arranged symmetrically with the lens group above around the aperture group and sixth lens group. By adjusting the aperture size of the diaphragm, it can adjust the numerical aperture of the lithography projection target, thus increasing the ability of the lithography projection target to be suitable for different scenes. In addition, setting the focal length of each lens group can increase the numerical aperture of the lithography projection objective lens, and improve the accuracy of the lithography projection objective lens.

The first lens group G1, the third lens group G3, the fourth lens group G4, the sixth lens group G6 have a positive refractive power, the second lens group G2 and the fifth lens group G5 have negative refractive power. The optical power is equal to the difference between the image side beam convergence and the object side beam convergence, and represents the ability of the optical system to scatter light. The higher the absolute value of the light energy, the greater the bending strength of the light, and the weaker the bending ability of the light. When the light energy is positive, the refraction of the light is convergent, otherwise it is bifurcated. Optical power can be used to characterize a specific refractive surface of a lens, to characterize a specific lens, or it can be used to characterize a system composed of multiple lenses.

Every lens kit and every lens in Stop STOP are spherical lenses. A spherical lens refers to the continuous curvature from the center to the edge of the lens. Both refractive surfaces of a spherical lens are spherical, while the curvature of an aspherical lens is constantly changing from center to edge. Therefore, the spherical lens is relative to the aspherical lens in terms of ease of processing. All lenses in embodiments of the present invention are based on spherical lenses, which reduces the lens processing cost of the lithographic projection objective, shortens the lens curing period, and improves the assembly and adjustment efficiency of the lithographic projection objective.

In short, Shanghai Microelectronics’ patented projection lithography objective lens, through the use of spherical lens design, reduces processing and manufacturing costs, increases numerical aperture, and is suitable for three-line ghi band. The applicable scene of the projection target is enlarged, and the precision of the lithography machine is improved.

Subtly charming zombie buff. Amateur analyst. Proud tvaholic. Beer fanatic. Web expert. Evil troublemaker. Passionate internet maven. Gamer. Food evangelist.